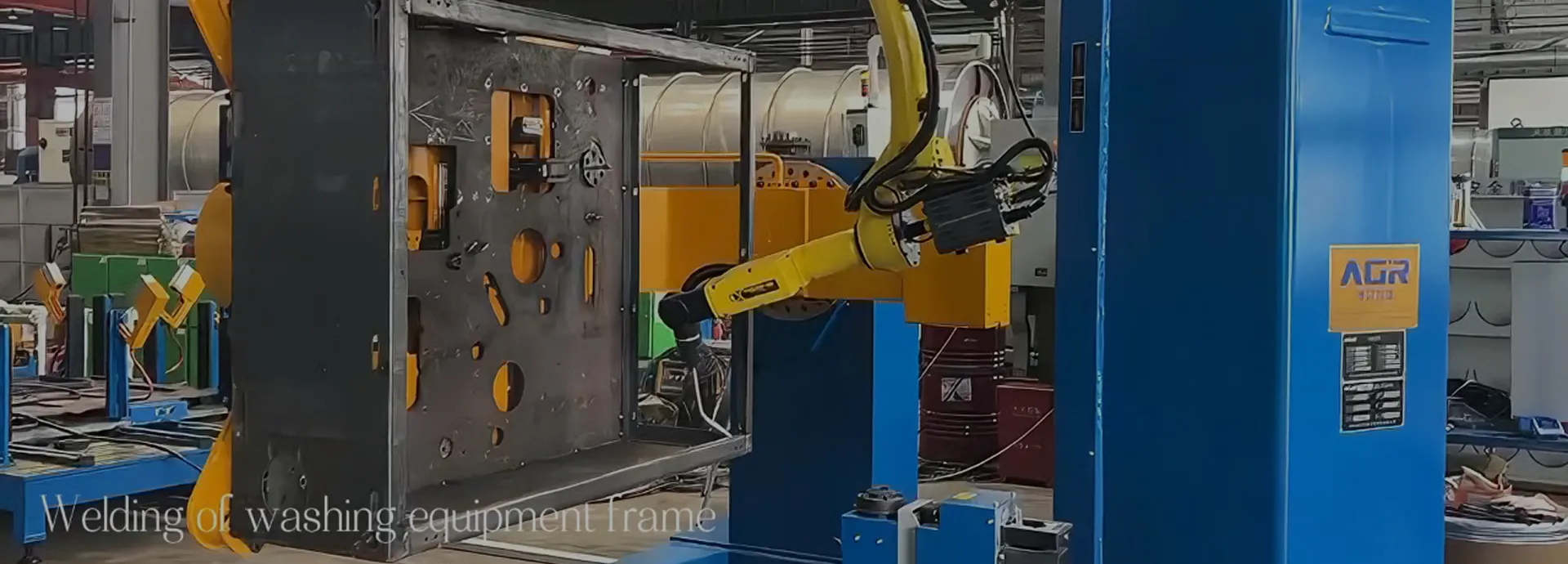

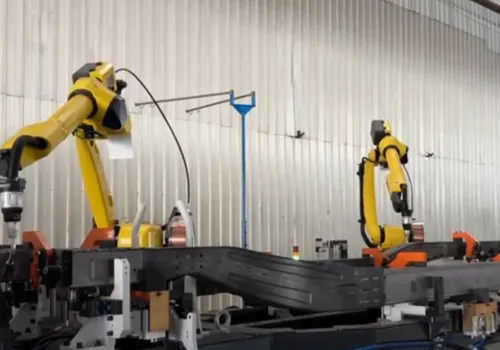

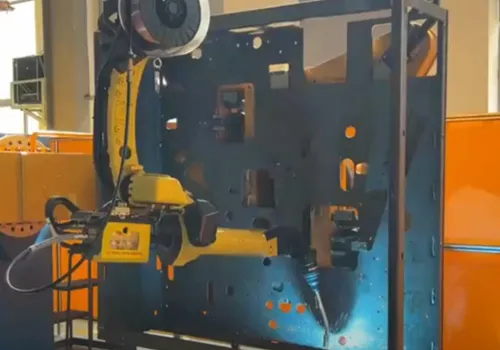

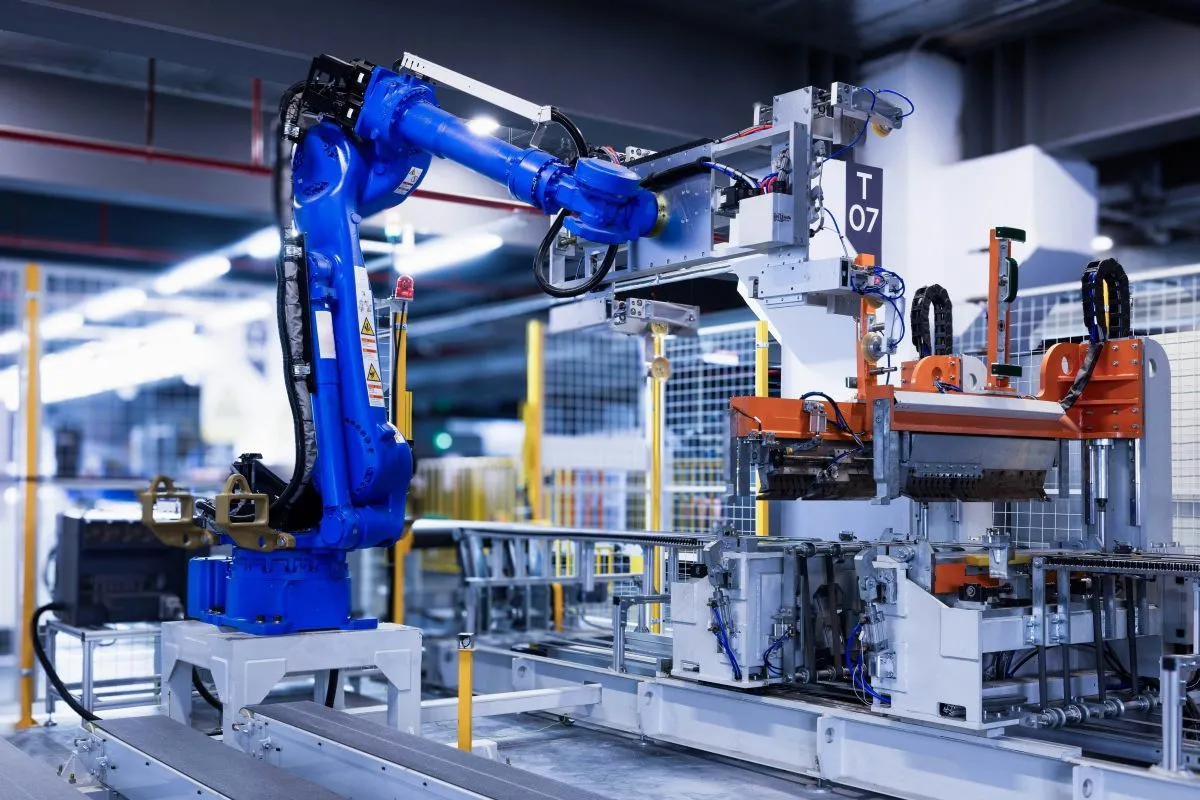

TURNKEY ROBOTIC AUTOMATION SOLUTIONS FOR GLOBAL INDUSTRIES

We provide customized robotic integration solutions for manufacturers worldwide, designed to boost productivity, reduce operating costs, and improve precision. From welding stations to robotic cutting and mobile units, our systems are built to meet real production demands, whether you need a standard setup or a tailored solution for your factory.