Komatsu Customer Visit at AGR Robotics

AGR Robotics Welcomes Komatsu for Technical Review of Gantry Welding Workstation

AGR Robotics recently hosted a visit from Komatsu, one of the world’s leading construction machinery manufacturers, at its Suzhou facility.

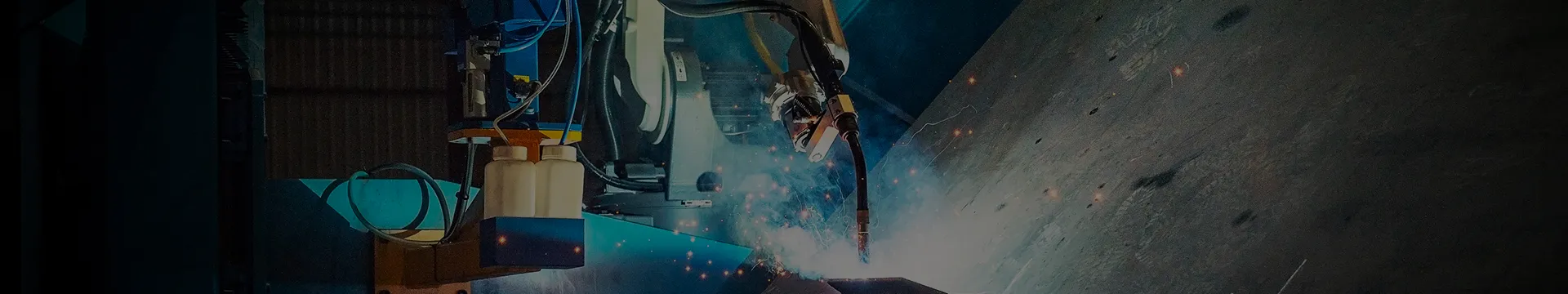

During the visit, Komatsu’s engineering team conducted an in-depth review and acceptance test of a customized gantry robotic welding workstation developed for large structural components such as booms and arms.

The workstation is equipped with:

Robot: Komatsu RAL12-6, designed for high-precision welding

Welder: Panasonic 700GL5 digital power source

Motion system: 3-axis gantry platform with extended travel for large-part coverage

Safety and auxiliary systems: gas pressure sensors, protective fencing, start/stop controls, and advanced safety interlocks

This high-performance workstation integrates multi-axis motion control, real-time weld monitoring, and dynamic path correction, achieving millimeter-level accuracy for complex geometries. The system improves weld consistency, reduces manual labor, and significantly enhances production efficiency for Komatsu’s heavy-equipment manufacturing.

The visit concluded successfully, marking another milestone in AGR Robotics’ collaboration with global OEMs. Both teams discussed future cooperation in intelligent welding, automation standardization, and smart factory connectivity.

Location: Suzhou, China

Date: August 2024